Precision Cleaning

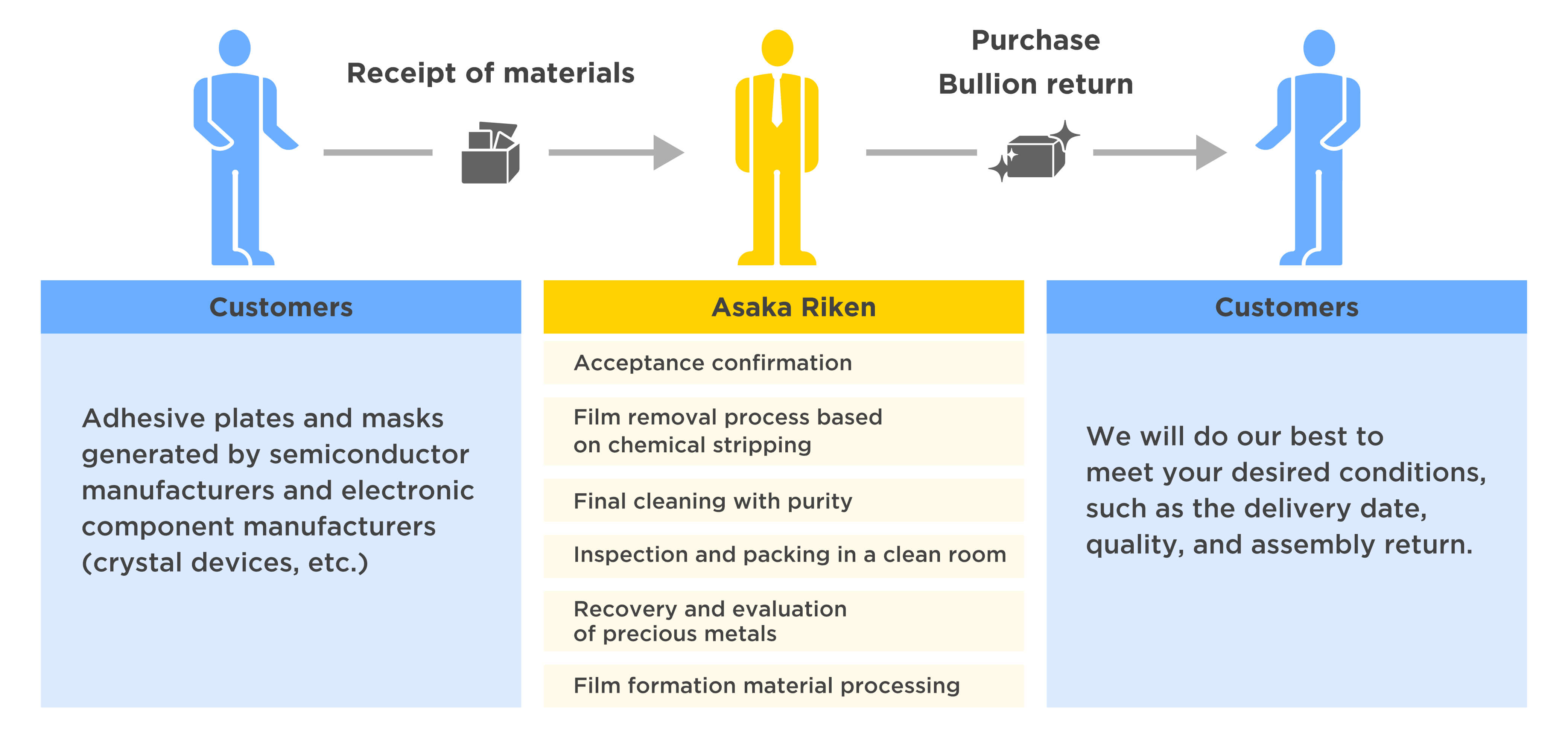

In addition to peeling, surface treatment, and precision cleaning of the film forming equipment, the peeled valuable metals are also recovered at the same time.

We clean jigs related to various film deposition equipment such as PVDs, CVDs, etching equipment, and vacuum equipment. Our chemical solution cleaning is implemented based on chemical stripping, and peeling, surface treatment, and final cleaning. This allows processing with less damage to the material compared to mechanical peeling and electrolytic peeling. The valuable metal recovered during the cleaning process are processed into film-forming material and returned upon customer request. We contribute to the improvement of customer's productivity through reducing costs and quality control.

Cleaning method

-

Sand blasting

Blasting is also available as mechanical peeling.

This is effective for jigs that require surface roughness to prevent film peeling. -

-

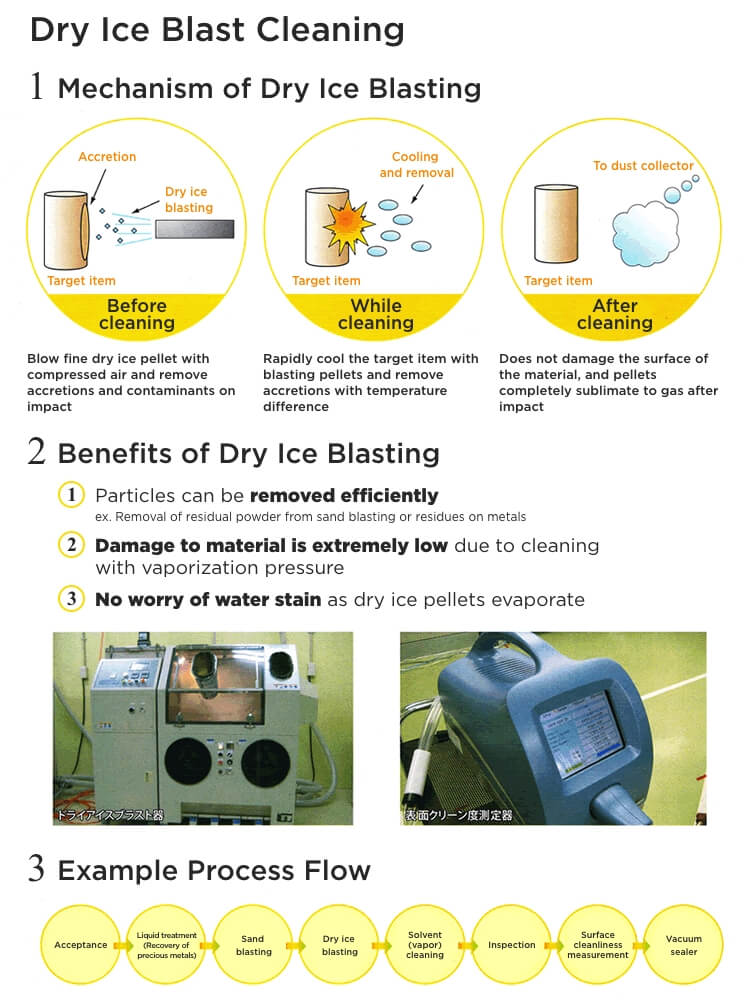

Dry ice blasting

This efficiently removes particles.

*Removal of sandblasting residue is also possible.

-