Environment Business

We contribute to environmental conservation by effectively utilizing resources through regenerating new etchants from used etchants.

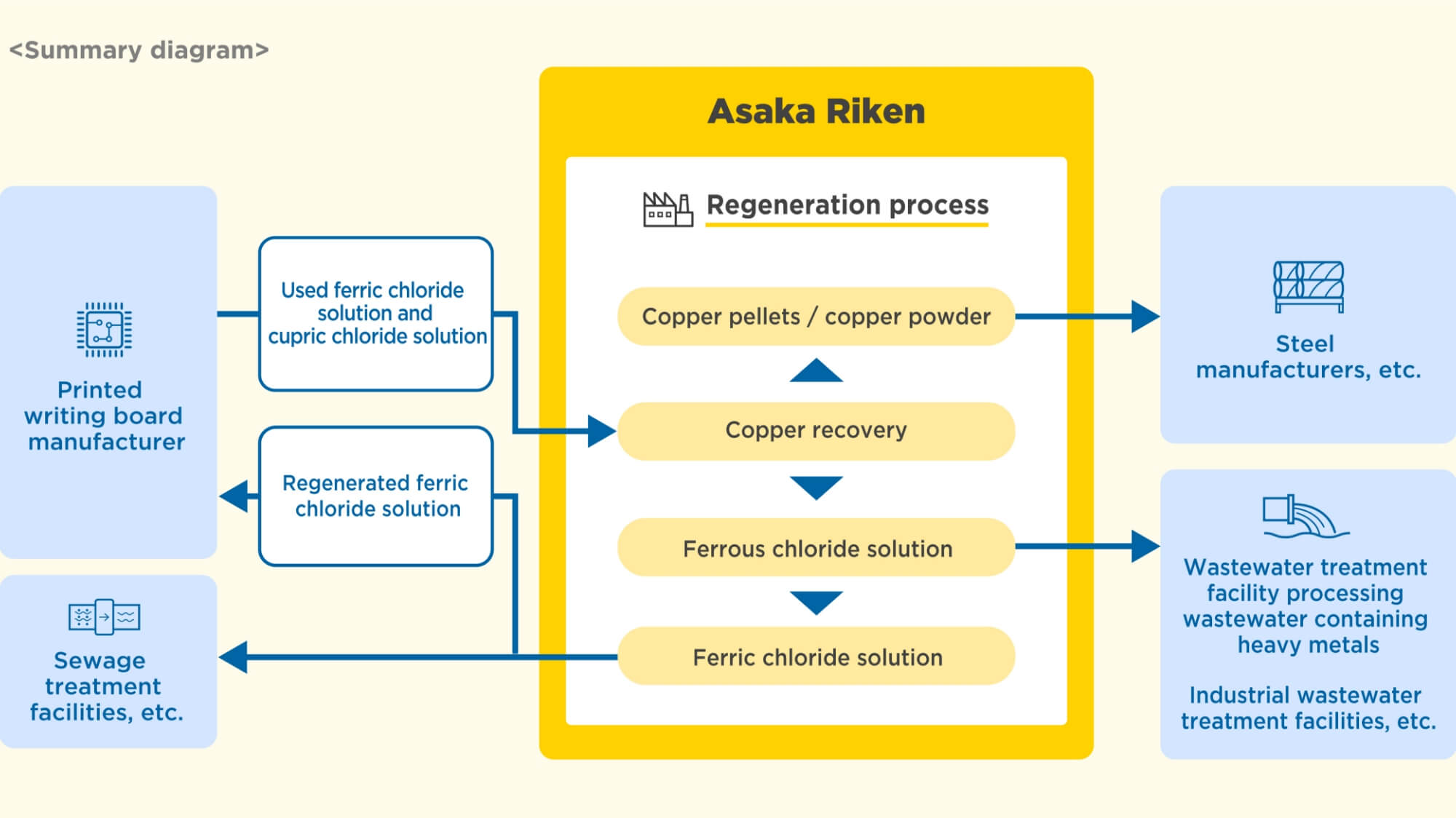

Asaka Riken's business spirit pursues reduction of waste at a maximum extent to reduce the burden on the environment. In our Environment business, we collect used etchants from printed writing board manufacturers, and recycle and sell it as new etchants. Furthermore, we recover and sell by-product copper. Environment business has supported the growth of our company since its establishment. We are proud of our high market share in the Tohoku region due to the trust and achievements we have built up through business transactions with our customers for half a century.

Service features

We regenerate used etchants and sell it as new etchants.

Used etchants discharged at printed writing board manufacturers are recycled into ferric chloride solution and sold to printed writing board manufacturers. This regeneration of used etchants produces multiple by-products in its process. We sell ferric chloride solution, which exceeds the required amount to be reused as new etchants, as a flocculant for wastewater treatment of sewage and various factories, and for the treatment of livestock feces and urine. Ferrous chloride solution is sold as a reducing agent for wastewater containing chromium. We also recover cooper contained in used ferric chloride solution and sell it to steel manufacturers as copper pellets and copper powder.